What Rims Fit My Car? The Ultimate Wheel Fitment Guide In 2024

If you are looking to get new wheels for your car, you may be wondering how to tell if the new wheels are going to fit.

There are a number of things you need to look for to determine if the wheels are going to fit, and in this guide I’m going to give you everything you need to know in order to be able to tell which wheels will fit and which won’t.

Let’s get right in to it.

How Wheel Sizes Are Read

When looking at wheel sizes, you are going to see a few numbers given that look like this: 5×114.3 18X10 ET20. Here’s what this means:

- 3 is the PCD or stud pattern

- 18X10 is the size of the wheel, where the first number is the wheel diameter and the second number is the wheel width.

- ET20 is the offset.

I will explain all of these in the section below.

Factors That Affect Wheel Fitment

There are a number of factors that will determine whether the new set of wheels are going to fit on your car.

First, there’s the question of whether they will physically bolt up to the car, and then there’s the question of whether they will fit without rubbing or hitting on anything such as the suspension, body or brakes.

Let’s cover each individual factor.

Bolt Pattern (PCD)

The first thing to determine before anything else is whether or not the PCD, otherwise known as the bolt or stud pattern, is correct for your car.

The PCD is the measurement of the bolt holes or studs on the car’s hub that the wheel uses to bolt to the hub. These holes or studs need to match the wheel’s in order for the wheel to even be able to bolt to the car.

How to Measure PCD

Measuring PCD is quite simple.

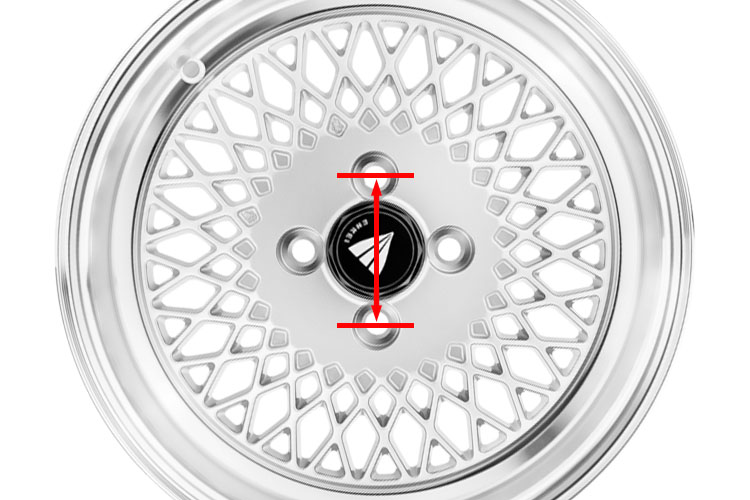

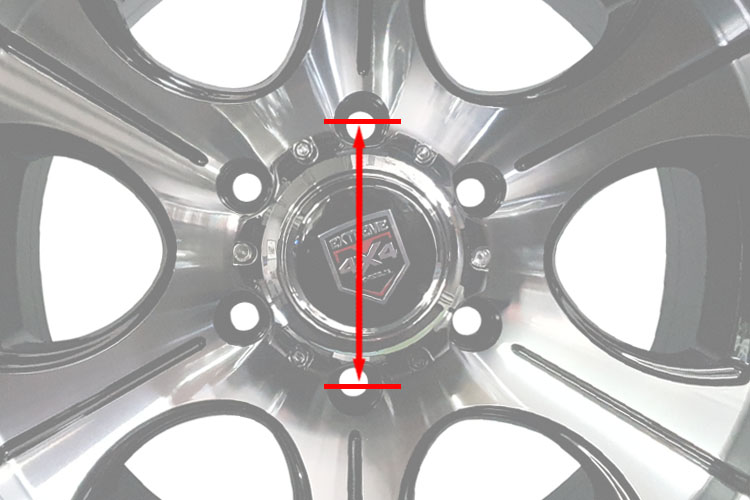

On wheels that have an even number of holes, such as 4 or 6 hole, you just measure from the center of one hole to the center of the hole on the opposite side.

In the case of 5 hole wheels, you need to measure from the center of the hole to the outer edge of one of the opposing holes.

In order to find your car’s PCD, doing a quick search online will easily tell you what you have. From there, you can search for wheels that have the matching PCD.

Common PCDs include:

- 4×100 (Common on smaller European and Japanese cars)

- 3 (Common on smaller Japanese cars)

- 5×100 (Common on VW & Audi from early 2000s, Subaru and some other cars)

- 5×112 (Mercedes and newer VW & Audi)

- 3 (Extremely common on many Japanese and American cars – the most common PCD)

- 5×120 (Common on BMWs and Holden/Chevy)

- 5×130 (Porsche)

This is by no means an exhaustive list but rather to give you an idea of what is out there.

Wheel Adapters

If you find wheels that you really want but they are not available in your PCD, it is possible to use wheel adapters to get them to fit.

Wheel adapters are similar to spacers except that they contain a different PCD for the wheel side, allowing you to fit wheels you would otherwise not be able to.

If using adaptors, you need to pay extra attention to the width and offset of the wheels to ensure they will fit with the added spacing of the adapter. More on this later in this guide.

Redrilling

It is also possible to get wheels redrilled to a different PCD, though this depends a lot on the design of the wheel as well as the original PCD.

Generally it’s not a good idea to redrill 4 bolt wheels to 5 bolt, due to the overlap of some of the holes, though people have done it.

Also, if the center bore is large and the PCD you need is small (4×100 for instance), you may find that the new holes are too close to the center to be safe to use, thus making it risky to do.

Redrilling is best avoided if possible, but if you are in a really sticky situation it may be the only solution.

Centerbore

Centerbore is the next thing you need to check in order to make sure the wheels will fit.

The centerbore is the hole in the center of the wheel in between the wheel stud holes.

Most aftermarket wheels are made with large centerbores in order to fit a wide range of vehicles.

However, if you are looking at factory wheels from another car, or aftermarket wheels designed for a specific car, you need to make sure the centerbore is the same size or bigger than your car’s.

For larger centerbores, it’s important to get hubcentric rings that match your car’s hub and the wheels centerbore, in order to allow the wheels to center properly and the hub to take the load.

Most cars are not designed for the bolts to take the load, only to hold the wheel on, so running without hubcentric rings can cause vibration issues and in extreme cases the wheel to fall off.

For smaller centerbores, it is possible to get them machined out to a larger size as long as the difference is not too big. Some cars only have a difference of a few millimeters, in which case this option would be suitable. However, it does involve messing around and finding a machine shop who can do it.

Diameter

Once you know that the wheels are actually going to bolt on to your car, it’s time to decide on the sizes.

The diameter is one of the obvious ones and is the measurement of how big the wheel is. Wheel diameter is always given in inches (with the exception of TRX wheels which are very rare and no longer made) and is the first number given in a wheel size. For example, a 15×7 wheel means 15 inch diameter, 7 inch wide.

Most wheels are between 15-19”, though they can go as small as 13” (or in the case of Minis, 10”) and as large as 28” or more in extreme cases.

Wheel diameter isn’t only about looks, though it certainly plays a bit part in the appearance of the car. The wheel diameter is also going to affect your tyre size options, and it will also affect the handling as well as the ride comfort of the car.

You need to factor all of these into consideration when selecting the diameter of the wheels.

We will diameter in more detail a bit later in this guide.

Width

Width is another important metric that you need to be aware of when selecting wheels.

The width of the wheel is going to significantly impact how the wheels fit, as well as how wide tyres you will need to run.

Width is also measured in inches (even though tyre width is usually in millimeters) and is the second number given on a wheel size. So to use the previous example of a 15×7 wheel, where the 15 is the diameter of the wheel, the 7 means 7 inches wide.

We will discuss the affects or increasing or decreasing wheel width a bit later in this guide.

Offset

The offset of the wheel will determine how far in or out the wheel sits in relation to the car. It is measured in millimeters and is given as a number after “ET”. The number after the ET is the offset measurement, so if the wheel has an offset of ET20, it means the offset is 20mm.

Wheels with a low offset will stick further out, and wheels with a higher offset sit further in.

You need to pay attention to the wheel offset when choosing new wheels, especially if the width is different from the factory wheels.

If you need help figuring out wheel offset or want to know more, check out my detailed wheel offset guide.

Brake Clearance

While this is generally only an issue for cars that have big brakes, you need to make sure that the wheel design you are looking at will actually clear the brakes.

Even if the diameter is big enough, the wrong offset or wheel face design can cause interference with brake calipers, meaning the wheels won’t fit.

An easy way to tell is to see if any other car like yours runs the same wheels. Otherwise, if you are unsure, test fitting at a local shop is a good idea if possible.

Make sure to keep this in mind when selecting new wheels.

How Is Wheel Size Measured

Measuring the wheel size may not be as obvious as you may think. It’s not always a case of measuring a wheel from edge to edge, as you are about to see.

Diameter

The diameter of the wheel is measured by the width of the barrel, not the width of the face of the wheel.

This means you can’t just take a tape measure and measure from edge to edge to get the measurement, as you will get the wrong size.

Typically, the edge to edge measurement will be 1.5 inches more than the true diameter, but the best way to measure is to see what size is stamped on the wheel, or see what tyres the wheel has mounted (if it has tyres).

Width

The wheel width is measured in inches from bead to bead, not edge to edge.

Similarly to the diameter, if you measure from edge to edge, you will get a measurement about 1 inch larger than the actual width of the wheel.

Wheel widths typically come in increments of half an inch, but there are cases where some wheels may have ¼ inch increments, so be careful when measuring in order to make sure you get the right width.

Things to Know When Changing The Size Of Your Wheels

Changing the size of your wheels can have a significant impact on several things including how your speedo reads and the car’s performance, so you need to be aware of these when selecting your wheel sizes.

Rolling Radius

One of the biggest things to take into account is the rolling radius of your wheels.

The rolling radius refers to the total diameter of the whole tyre rather than the wheel itself.

This is important because increasing or decreasing the rolling radius will have an effect on the cars acceleration as well as the speedometer.

As you increase wheel diameter, you will want to go for a smaller tyre sidewall in order to keep the rolling radius as close to factory as possible.

While it’s ok to be a couple of millimeters out from factory, making significant changes to the rolling radius is generally not a good idea unless you know what you are doing and have a reason for doing so.

How to Calculate Rolling Radius

In order to calculate the rolling radius, you either need to find out what the total diameter is of the tyre size you are considering for your new wheels, or you need to calculate if by converting the wheel size into millimeters, then calculating the tyre sidewall size and adding the two together (x2 on the tyre sidewall).

Increasing Wheel Diameter

If you are looking at increasing or decreasing the wheel diameter, there are a couple of other considerations to make aside from the rolling radius

Tyre Options

Firstly, your options for tyres is going to be greatly affected by the wheel diameter, especially when it comes to certain widths.

Some wheel diameters have infinitely more tyre options that others, and if you pick a less common wheel size the tyres can get quite expensive, if they are even available.

Fitment Issues

Another thing to consider if increasing wheel size is fitment issues. Generally, you are pretty safe to increase wheel size about 2-3” more than factory, but beyond that you can start running into clearance problems and other issues.

Performance

Also keep in mind that the bigger the wheel is, the heavier it’s going to be, which can have a pretty significant impact on both handling and acceleration the bigger you go.

Ride Comfort

Going with a bigger wheel size can also significantly affect the ride comfort if you are forced to run very thin tyres in order to fit the large wheels.

The thinner the sidewall, the worse the ride will be. Keep this in mind when choosing wheel diameters as you may find the decrease in ride comfort not worth the extra street cred.

Decreasing Wheel Diameter

If you are looking to go with a smaller wheel size, there are a couple of factors to consider here also. It’s generally not advised to go smaller than the factory wheel size as you will run into fitment problems as well as affect the car’s performance. This is pretty uncommon, but if you are looking to do this, where are some things to consider.

Clearance Issues

Your biggest problem is going to be clearance with the brakes. Most of the time you will find that small wheels will hit the brake caliper with the barrel and there is nothing you can do to solve this aside from get difference wheels.

Some wheel designs have more space and will allow you to run a diameter that other wheel designs in the same diameter would not. So if the interference in question is a few millimeters, you might be able to find a different wheel that fits.

Handling

As you go smaller in wheel diameter, you will generally have to run a thicker sidewall tyre. While this will result in a more comfortable ride, you will experience less responsive steering. If you are concerned with the handling performance of your car, this usually is not the best way to go about maximizing it.

Acceleration

If you decrease the rolling radius of your wheels, you will find that your car accelerates faster. This is because you are affecting the gearing of the transmission by changing the rolling radius. In some instances this can be favourable, but generally it’s a good idea not to mess with it unless you know what you are doing.

Increasing Width

Increasing the width of wheels is an incredibly popular modification both for performance as for looks.

If you are considering getting wider wheels, there are two main things you need to take into account.

Clearance & Fitment

Clearance is often the biggest issue you will run into with wider wheels. Generally speaking, you will normally get away with 1-2 inches of extra width from the factory sizes, but beyond that you will start rubbing on things.

Generally you will either rub on the suspension or on the body, or both if you go wide enough. I will discuss solutions to rubbing issues in more detail in a bit.

Tyre Sizes

The width of the wheel is also going to impact which tyre sizes you can run.

Generally speaking you will need to get tyres that match the width of the wheel. In most cases, the whole purpose of running wider wheels is to fitter bigger tyres for more grip (unless you are in the stance crowd).

Now, you do have some leeway here, as a tyre of a certain width will fit several wheel widths. This can also be used to your advantage in order to fit wheels that are slightly too wide. I will discuss this more in the tyre stretching section a bit later on.

Decreasing Width

Decreasing wheel width usually has very few problems, aside from the fact that you will lose some contact patch because you have to run thinner tyres.

However, if a wider wheel fit on the car, there is no reason why a narrower wheel won’t, so generally speaking you should be fine by going down a size in width.

Just be aware that you will probably have to get narrower tyres as well.

Wheel Nuts / Bolts (Pitch)

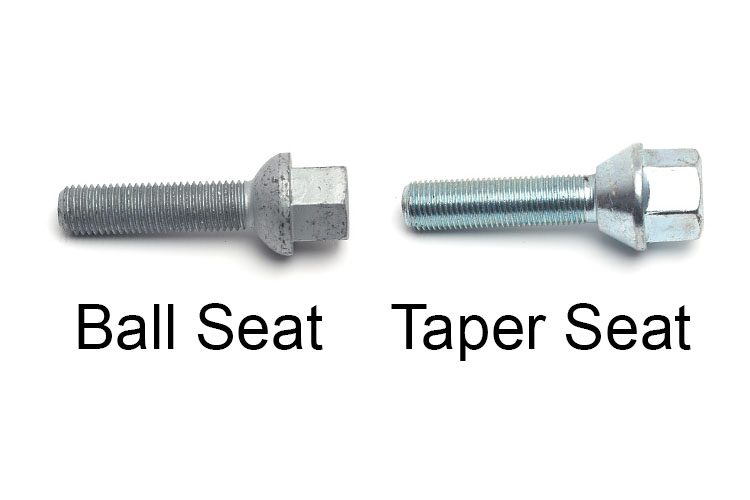

While this won’t affect how the wheels fit, aftermarket wheels tend to require different wheel bolts or nuts compared to factory wheels.

While the thread is the same, the difference likes in the seat of the bolt or nut.

Many factory wheels such as steel wheels use ball seat nuts or bolts, while most aftermarket and aluminium wheels use a tapered seat ball or nut.

It is generally a good idea to get the correct nuts or bolts to suit the wheels you are going to install.

While it is technically possible to use the incorrect type of nut or bolt, it is not recommended because you could damage either the wheel or the nut/bolt, and you also risk them not tightening correctly and coming loose.

A new set or nuts or bolts should not cost more than $100 if that, so it pays to just get the right ones.

How Ride Height Affects Wheel Fitment

The ride height of your car is something you also need to consider when selecting wheels.

The higher your car sits, the more room you will have for the wheels are tyres, meaning you can fit wider wheels and tyres.

As you lower the car, you will start running into clearance issues on the body side, which means you will either need to run narrower wheels and tyres or stretched tyres to try and get them to fit (more on this in a bit).

Also keep in mind that negative camber tends to increase as the car gets lower, which can give you some extra room to play with when it comes to widths, but this is highly dependent on each individual car.

If you are really low to the point where the wheels are tucking, no amount of tyre stretch will save you, you will have to get wheels that fit under the fenders.

Keep this in mind when selecting wheel sizes and ideally have the ride height sorted first so that you can make a proper judgement call.

How to Solve Rubbing Issues

If you find that your new wheels and tyres are rubbing after you have installed them, there are a couple of things you can do to try and remedy the situation.

Fender Rolling

If your tyres are rubbing on the fenders, also known as guards, the most common solution is to roll the fenders.

Most cars have a lip on the inside the fender which can be as wide as 25mm (an inch) and really cuts down on the room you have for wheels and tyres.

Rolling the fenders will push this lip up against the body, essentially removing it and giving you that extra bit of room which often times will be enough to eliminate any rubbing altogether.

In extreme cases with really wide wheels, you may find that you have to also flare the fenders out a bit to allow them to fit.

In my opinion this usually doesn’t look very good, but a lot of people do it and if you have just spent decent money on the wheel and tyre setup, it may be your only option.

Trimmer Inner Covers

Many cars also have a plastic cover the goes on the inside of the wheel well, and this can be the cause for rubbing.

These covers are only there to keep dirt and debris out, but you can trim them where the rubbing is happening to eliminate it.

This cover is usually plastic, so you don’t even have to trim it if you don’t want to as it’s not going to cause any damage to the tyre, and eventually it will probably take care of itself. You might just smell some burning plastic until that happens.

Spacers

If you find that your wheels are rubbing on something on the inside on the wheel well, usually the suspension, you can use wheel spacers to push them out a bit and solve this problem.

If you do decide to use spacers, make sure you measure how much room you have to work with on the fender side. If you went for a really wide fitment, you might find that you don’t have much to work with and may need to roll or flare out the fenders to make room.

Tyre Stretch

Another way to solve fitment issues and rubbing is to run stretched tyres.

Stretched tyres are tyres that are slightly too small in width for the wheel and are “stretched” on.

They are often used when the tyre itself is rubbing but the wheel can fit, so stretching a smaller tyre on gives you extra room to work with.

It’s generally not a very good idea to go crazy with this as the more you stretch the tyre, the less safe it is and the more likely you are to have problems such as the tyre debeading or air escaping.

However, going down a size or two in tyre width, such as from a 225 down to a 205, is generally ok and could solve any rubbing issues you have.

What Other Car’s Wheels Will Fit My Car?

There are many wheels from one car brand that often fit on another car brand.

In order to determine whether another car’s wheels will fit your car, you need to figure out the same details as you would with aftermarket wheels.

You need to see if the PCD (stud pattern) is the same as your car, if the centerbore is the same or bigger, and if the size and offset of the wheel will fit.

If the PCD is the same, the centerbore is the same or larger, and the wheel size is the same or very close, then the wheels will fit.

Is There a Difference Between Alloy and Steel Wheels?

No, there is no difference between alloy and steel wheels when it comes to fitment. All the same fitment and size principles still apply, the material used to make the wheels makes no difference here.

- BC Racing BR Series VS Tein Flex Z Coilovers - April 15, 2024

- The Pros and Cons of Shock Body Vs Spring Perch Coilover Height Adjustment - April 13, 2024

- Monotube Vs Twin Tube Shocks: The Ultimate Guide - April 11, 2024