Cast Vs Flow Formed Vs Rotary Forged Vs Forged Wheels: The Ultimate Guide

If you are shopping for new wheels, you’ve no doubt come across a range of terms describing the different types of wheels. There are so many different terms used to describe wheels and how they are made that it can get confusing to know what’s what without being an expert.

In this post, I’m going to explain what all these terms mean, along with the differences in each, in order to help you to select the right wheels for your car.

What Are Cast Wheels?

Cast wheels are the cheapest and easiest wheels to make, but are also the weakest and heaviest. These are the wheels you see at the low end of the price range, the $150-200 mark. Replica wheels and cheap no name wheels are almost always cast, as well as many OEM wheels.

How Cast Wheels Are Made

Cast wheels are made by pouring molten liquid alloy into a mold that is shaped like the wheel.

There are a couple of different methods used for casting.

Gravity casting is the most common casting process which involves just pouring the alloy into the mold, and can result in inconsistencies in the aluminium, which results in a weaker wheel.

Another casting process is pressure casting, which results in a higher quality wheel, because the pressure forces the aluminium into shape, making it more dense and reducing the risk of imperfections. However, this is more complicated and expensive, so is not as common.

Once the casting has cooled down, the wheel is removed from the mold and cleaned up and trimmed to remove imperfections. Any drilling such as for PCD holes is also done.

Here’s a video that shows the casting process:

Pros

- Casting is the quickest and cheapest method of producing wheels, which is why so many cheap wheel companies use it

Cons

- These are the lowest quality wheels produced

- Cast wheels are the heaviest of all wheels, as they require more material to achieve the same strength and stiffness as other wheel types

- Casting can often have inconsistencies, such as the aluminium being porous due to gas formations, which can cause the material to not be uniform and result in weakness

- Cast wheels are almost impossible to repair safely, and must be replaced if damaged

Can Cast Wheels Be Good Quality?

Yes, there are many good quality cast wheels which are more than strong enough to handle street use and occasional track use.

However, a good quality cast wheel will generally be heavier compared to other wheel types in order to be sufficiently strong, which doesn’t make it ideal for performance.

Cast wheels are generally not a good idea if you intend to spend a lot of time at the track, as they are not really made to withstand the constant abuse that track driving usually delivers.

What Are Flow Formed Wheels?

Flow forming is a method that is a kind of hybrid between forging and casting. Flow Forming wheels are often considered the best value for money and are a good middle ground between cast and forged wheels.

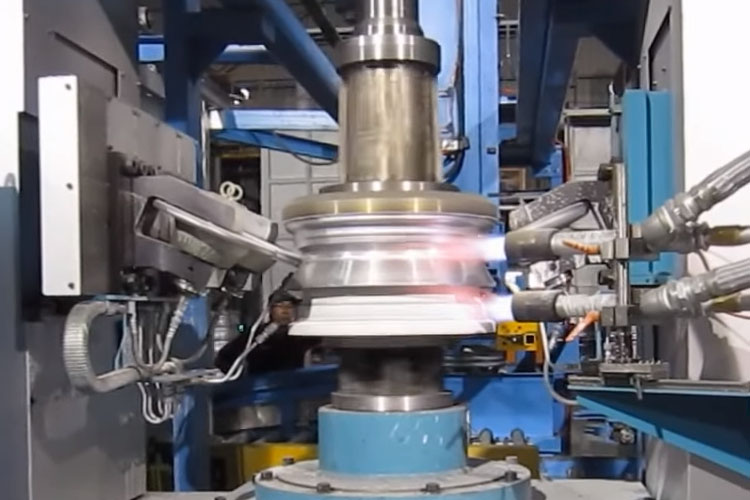

How Are Flow Formed Wheels Made?

The face of the wheel is made by casting, with excess material on the back side to form the barrel.

The wheel is then put on a machine and spun at high speeds, while heat is applied to the outside of the wheel. Rollers are then used to apply pressure to the heated excess material to form the shape of the barrel.

The benefit of this is that it creates a stronger barrel with a more uniform structure that can absorb impacts much better than a regular cast wheel.

Using this process, flow formed wheels can be made to be both lighter and stronger than cast wheels, and many wheel companies use this process to make affordable wheels that are comparable to forged wheels in terms of weight and strength, but at a much lower cost. Enkei wheels are a perfect example of this.

Here’s a video showing the flow forming process:

Pros

- Flow forming results in a stronger wheel than regular casting

- Flow formed wheels are significantly lighter than cast wheels by up to 25%

- Flow forming is still relatively cheap, much cheaper than forging

- Much more consistent material than cast, making the wheel more durable

Cons

- More expensive than casting, but not by much

- Most flow formed wheels are not quite as light or as strong as forged wheels

Are Flow Formed Wheels Good?

Yes, flow formed wheels are very good and are some of the best value for money wheels you can buy. They are much stronger and lighter than regular cast wheels, while being significantly cheaper than forged wheels. This makes them a great option, especially where performance on a budget is required.

Are Flow Formed Wheels Weak?

No, flow formed wheels are not weak. Flow formed wheels are significantly stronger than cast wheels, and are often almost as strong as forged wheels.

Are flow formed wheels that much stronger than cast?

Yes, flow formed wheels tend to be significantly stronger than cast wheels, due to the flow forming process which results in a much more uniform structure of the metal.

Are Flow Formed Wheels the Best?

No, technically speaking, forged wheels are the best because they offer the best combination of strength and stiffness. However, flow formed wheels are very good and are often the best value for money.

Is It Safe to Use Flow Formed Wheels In Winter?

Yes, flow formed wheels are perfectly safe to use in winter. There is no reason why a flow formed wheel would not be able to handle cold winter weather.

Which Brands Make Flow Formed Wheels?

Most of the best wheel brands have a number of flow formed wheel models in their line-up. These include:

What Are Rotary Forged Wheels?

Rotary forging is exactly the same thing as flow forming. The term “rotary forging” is used purely for marketing purposes because people know that forging is a good thing but don’t exactly know why or what it is, so many companies like to call their flow formed wheels “rotary forged” or even “flow forged” to make buyers think they might be forged. Be wary of this when shopping for wheels.

Flow Formed Vs Rotary Forged Wheels

Flow formed and Rotary Forged is exactly the same thing. Companies like to call their flow formed wheels “rotary forged” for marketing reasons to make them sound like they are forged, but they are not.

Are Rotary Forged Wheels Good?

Yes, rotary forged wheels are good. They are much strong and lighter than cast wheels and are often the best value for money wheels you can buy.

Are Rotary Forged Wheels Strong?

Yes, rotary forged wheels are strong. They are significantly stronger than cast wheels due to the way the barrel is made, but they are usually not quite as strong as truly forged wheels.

Do Rotary Forged Wheels Crack?

Rotary forged wheels can crack, usually on the face side due to that part of the wheel being cast. However, cracking is much less common than on regular cast wheels.

Rotary Forged Wheel Brands

Some wheel brands that make rotary forged wheels include:

- BBS

- Enkei

- Konig

- TSW

- Vossen

- Forgeline

- Kansei

- HRE

- And more

What Are Forged Wheels?

Forged wheels are considered the cream of the crop and are often associated with ridiculously high price tags of $2000 per wheel or more.

Forged wheels are the best combination of strength to stiffness currently available, making them the best choice when performance is the priority and money is no object.

How Are Forged Wheels Made?

Forged wheels are made from a solid block of T6 6061 aluminium that is heated and pressed using a lot of pressure to force the alloy into shape, which causes it to become uniform in grain structure, giving it the strength it needs and removes the possibility of being porous and other structural issues.

This results in very strong and consistent metal which allows a lot of material to be machined off while still maintaining the strength required to have a strong wheel. Compared to cast wheels, forged wheels can have significantly less material while maintaining the same or more strength, which is what allows them to be so light.

Unfortunately, the forging process is complex and expensive, which is why these wheels cost so much. Forged wheels are almost always made to order, which means you need to wait for them to be made, which can take up to 6 week or more. The positive of this is that most companies allow you to customize the wheels in almost every way, so you can get the perfect setup.

Forged wheels are often available in monoblock and multi-piece configurations.

Here is a video showing how forged wheels are made:

Pros

- Significantly lighter for the same or more stiffness and strength as cast wheels

- Absorbs impacts much better

- Allows for unique designs that you cannot safely make with casting (thinner spokes for example)

- Many customization options due to being made to order

- Often come in multi piece configurations and many different sizes

- Can be repaired and usually bend rather than crack

Cons

- Usually requires waiting period for the wheels to be custom made

- Extremely expensive due to the more complicated manufacturing process

Are Forged Wheels Worth It?

The answer really depends on what you need from your wheels and how big your bank balance is.

If you are truly balling and you either want the best wheels to show off with, or you want the absolute most performance, forged wheels are definitely your best option.

However, for most people, forged wheels only provide marginal benefits over flow formed wheels and therefore are not really worth the significant difference in price.

It really does come down to your personal needs as well as your budget.

Cast Vs Forged Wheels Durability

Forged wheels are significantly more durable than cast wheels to the point where it’s not even comparable. A forged wheel that is lighter with less material is still much more durable than a cast wheel.

Rotary Forged Vs Forged Wheels

As explained earlier in this post, rotary forged wheels are in fact not forged at all but are flow formed, and share very little similarity to forged wheels. Rotary forged wheels are generally weaker and heavier than forged wheels, though they are still a great option for people with lower budget. If you can afford it, forged wheels are the best.

What Is Stronger Rotary Forged or Forged Wheels?

Forged wheels are almost always stronger than rotary forged wheels. Rotary forged wheels have a cast center and lip, which is weaker than a fully forged wheel.

What Are Forged Wheels Made Of?

Practically all forged wheels are made of T6 6061 aluminium, which has been heat treated and pressed to significantly increase its strength and structural consistency.

What Are the Best Forged Wheels?

Some of the best forged wheels are made by brands including:

- Volk (Rays Engineering)

- BBS

- Work

- SSR

- Vossen

- Rotiform

- Forgeline

- HRE

- And more

What Are the Cheapest Forged Wheels?

Forged wheels will typically cost you at least $1000 per wheel. That being said, there are some cheaper options, with one of the cheapest being Titan 7, who have forged wheels starting at around $2100 for a set of four.

Some FAQ About Different Types of Wheels

What are the Strongest wheels?

Forged wheels are the strongest wheels that you can buy

What Kind of Wheel Is Better Cast or Flow Formed?

Flow formed wheels are better than cast wheels. Flow formed wheels have a cast center and lip, but the barrel is flow formed which makes them significantly stronger than regular cast wheels, allowing them to also be lighter.

- BC Racing BR Series VS Tein Flex Z Coilovers - April 15, 2024

- The Pros and Cons of Shock Body Vs Spring Perch Coilover Height Adjustment - April 13, 2024

- Monotube Vs Twin Tube Shocks: The Ultimate Guide - April 11, 2024