What Are 2 & 3 Piece Wheels? The Ultimate Guide to Multi Piece Rims

If you are looking at wheels for your car, particularly if you want something specific, flashy and expensive, you’ve no doubt come across terms like split rims, multi-piece, 3-piece or others.

They often come in crazy designs, amazing colors and ridiculously high price tags.

In this guide, I’m going to explain everything you need to know about multi-piece wheels, otherwise called “splits” or “split wheels”, why they cost so much and why you would want some.

The History Of Multi-Piece Wheels

The first multi-piece wheel was made by SSR in 1971 as a wheel for motorsport use.

The original purpose of multi-piece wheels was to make it easy for race teams to customize wheels to suit their needs, often for only one car or one race.

Back then, it was not easy to get a mold made for a very limited run of wheels, so multi-piece wheels allowed them to put together what they needed and quickly change if necessary.

They also made it easy to repair a wheel when it got damaged, as they could just swap out a damaged lip or barrel and be on their way.

There were only a few companies that made multi-piece wheels at the time, such as BBS, Work, SSR and Volk, so they were mainly only used for racing.

In the decades since, as people began customizing their cars more and more and wheels because cheaper and easier to produce, multi-piece wheels became extremely popular.

What’s interesting is that motorsports have since turned to flow formed and forged monoblock wheels as they tend to be are stronger and lighter, but multi-piece wheels have remained as the choice for people who want flashy wheels that stand out.

Especially with the recent resurgence of widebody conversions, multi-piece wheels allow people to build custom cars and get wheels that fit their exact specifications, which are often much wider than most off-the-shelf wheels are made.

They are also extremely popular partly because they are expensive, so they severe as a status symbol, and partly because they are extremely customizable, allowing you to choose every piece of the wheel to your liking, from the color of the face and barrel to the style and finish of the lips and even the finish and material of the hardware.

Multi-Piece Wheel Construction

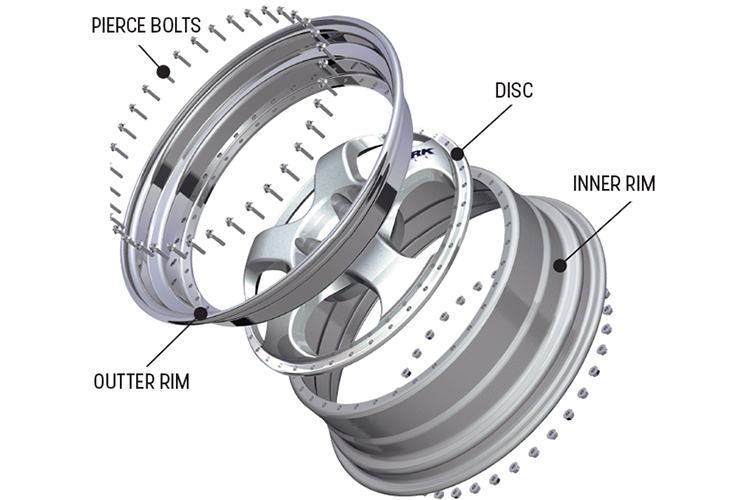

There are a number of different construction options for multi piece wheels. Both 2 piece and 3 piece can be made and assembled using a variety of different methods, depending on the design.

The parts are either bolted or welding together, and then silicone is used to seal the joining parts so that air doesn’t escape from the tire (except for 2 piece wheels that have a single piece rim and a face that bolts or is welded to it).

Here are the different constructions you will typically find for multi piece wheels:

2 Piece Construction

There are a number of different ways that 2 piece wheels can be constructed.

2Piece Welded

The 2 piece welded construction is one of the most common ones you will see today. Work Wheels are one of the most popular brands that offer wheels like this.

These wheels feature a rim that is a single piece, and a face that gets inserted at the desired offset and welded to the rim.

This allows for an almost infinite mount of offset options for the wheel, while making for strong wheels and eliminating the possibility of air leaking from the join.

2 Piece Barrel & Face + Lip

This construction is not very common for a 2 piece wheel. It features a barrel and face as a single piece, and then the lip as the second piece, allowing you to swap the lips for different sizes to increase the wheel width and lower the offset.

One of the most notable wheel that uses this construction is the BBS RC 090, also known as the BMW Style 5.

2 Piece Rim + Face

This used to be a common 2 piece construction and you will find many wheel models from the early 2000s that used this, such as the Volk GT-C.

This construction features a single piece rim that has a flange, and the face bolts to that flange. Similar to the welded 2 piece design except for the fact you were limited in offset by where the flange is.

3 Piece Construction

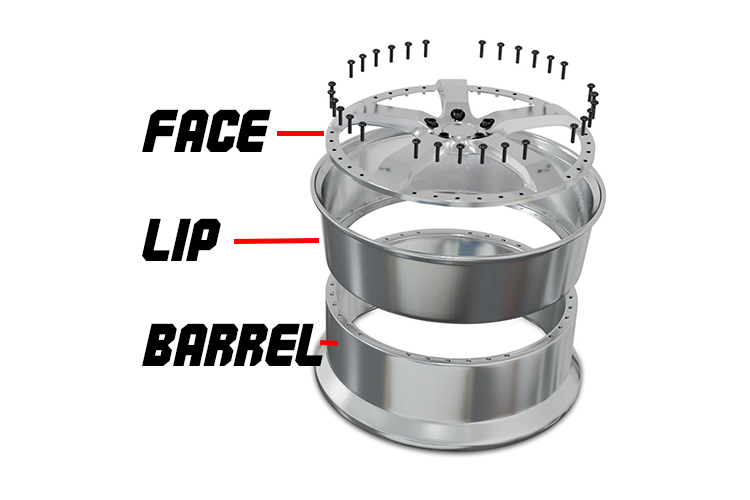

3 piece wheels all typically feature the same basic construction – a lip, barrel and face. However, depending on the design, these piece can be put together in a number of different ways.

Sandwich

The most common 3 piece construction is called the sandwich, because the face is “sandwiched” in between the lip and barrel.

This construction allows the lips and barrels to be interchanged for different sizes, and you can even reverse mount the face to lower the offset (more on this later).

Front Mount

Probably the second most common construction, on this one the barrel goes at the bottom, then the lip, and then the face on top.

The front mount construction is often used when the design of the face would interfere with the flange for the lip, so the face has to go on top.

Rear Mount

This one is rather uncommon and is the opposite of the front mount, where the face would be mounted under the barrel, with the barrel and lip on top.

This would only be possible with faces that were designed for the sandwich construction, and wouldn’t really yield any benefit other than lowering the offset by a few millimeters.

Reverse Mount

Reverse mounting is when the face is mounted backwards so that the barrel is on the front of the wheel and the lip is on the back.

This is sometimes done as a quick and cheap way of lowering the offset of the wheels, as it would reverse the offset.

That means if the wheels previously had an offset of 20, if you reverse mount the faces they would now have an offset of -20.

You won’t really find any wheels sold new like this, mostly because there is no need since you can customize 3 piece wheels to your specs, but some people do this with second hand wheels or wheels they had to get a lower offset fitment without having to buy new lips and barrels.

Manufacturing Methods

These days the vast majority of multi-piece wheels are made out of forged wheel centers and spun barrels and lips, most of which are made out of 6061 T6 aluminium.

This means that they are particularly strong, since forged wheels are typically the strongest type of wheel available.

However, there are models that feature cast centers, which can mean that they are slightly less expensive than the fully forged options. However, these will not be as strong.

Many older multi-piece wheels had cast centers, so if you are picking up a set of second hand wheels made in a previous decade, just be aware of this.

Benefits of Multi-Piece Wheels

Multi-piece wheels come with a range of benefits that you can’t get with monoblocks.

Customization

The most known and most obvious benefit is the high degree of customization.

Unlike monoblocks wheels where you are stuck with what’s made, multi-piece wheels allow you to customize literally every aspect of the wheel.

From the size and offset to the color and type of finish on the faces, lips and barrels, the type of center cap and even the hardware, you can choose every single thing to suit your needs and taste.

Most manufacturers of multi-piece wheels offer countless customization options to allow you to order exactly what you want.

But not only that, once you actually get the wheels, nothing stops you from pulling them apart and refinishing them to get a new look, or adapting them to a different car where a different size is required.

Variety of Sizes & Offsets

Unlike with monoblocks wheels where typically you are restricted to the sizes made, multi-piece wheels allow you to custom spec your sizes and offsets to fit your car perfectly down to the millimeter.

Not only that, but if you decide you want to change your car and add flares or a widebody, or put the wheels on a different car, you can swap out the lips and barrels to suit the new fitment requirements.

Custom One-Off Wheels

Multi-piece wheels almost always come custom made, which means that you get to order a unique, one-off set of wheels that no one else will have.

Anyone who attends car meets or shows will know the level of respect and admiration you get for something like this, so it’s another added bonus for spending so much on your wheels.

Quality

Because multi-piece wheels are so expensive, they are almost always extremely high quality. Most multi-piece wheels are made using forged parts, which means they are strong and durable, so you don’t need to worry about them failing.

While most people won’t want to risk their expensive custom wheels, most multi-piece wheels are capable of handling track use and hard performance driving. So if you ever decide to do it, you can be confident the wheels will handle it.

Hold Their Value

Multi-piece wheels tend to hold their value on the second hand market so you can sell or swap them later on for decent amount, particular if they are a hard to get model or some unique finish that you can’t get any more. A prime example of this are the BBS RS Prima Donnas, a very limited edition wheel that is highly sought after:

Downsides of Multi-Piece Wheels

While all this sounds great, there are a couple of downsides to multi-piece wheels.

Cost

One of the biggest downsides to multi-piece wheels is the cost.

Due to the fact that they are typically custom made and made using the most expensive methods (forging), they are typically extremely expensive.

By extremely expensive I mean $3500 for a cheap set, and I mean cheap. A typical multi-piece wheel set up will cost you $4000-8000, and some can be even more.

Not everyone is balling hard enough to afford wheels this expensive, but that is also what makes them special.

Weight

Despite the fact that they were originally for motorsport, multi-piece wheels actually tend to be pretty heavy when compared to other wheels.

This is because of the hardware, the sealant and so on which adds extra weight to the wheel, combined with the design and construction itself.

While many companies do their best to keep the weight down, they are not going to be able to compete with a set of forged monoblocks, for instance.

Maintenance

Multi-piece wheels do require some maintenance. Overtime, they can leak and bolts can come loose, so they do require occasional care to ensure they are doing their job.

While this is typically minor stuff, you don’t have any of this with a monoblock wheel, so it’s fair to mention it.

Order Wait Times

Another thing to consider when looking at ordering custom multi-piece wheel is the wait time for the wheels to get made.

While most companies claim that their lead time is 4-6 weeks, in most cases they take far longer than that and it’s not uncommon for people to be waiting up to 6 months for their wheels.

Wheel companies are notorious for taking extremely long to get the wheels to the customer, so be prepared to wait if you are ordering a set.

Should You Get Multi-Piece Wheels?

It really depends on what your needs and budget are.

If you are after wheels that look amazing, you don’t mind that they are heavy and you have the cash, multi-piece wheels are about as baller as it gets.

However, if you are looking for performance wheels, you are better of going with a lightweight set of forged monoblocks like Volk Racing or flow formed wheels like Enkeis.

Best Multi-Piece Wheel Brands

If you have decided to buy a new set of multi-piece wheels, here are some of the best multi-piece wheel companies I recommend checking out:

- BC Racing BR Series VS Tein Flex Z Coilovers - April 15, 2024

- The Pros and Cons of Shock Body Vs Spring Perch Coilover Height Adjustment - April 13, 2024

- Monotube Vs Twin Tube Shocks: The Ultimate Guide - April 11, 2024