What Is JWL, VIA, JAWA & TUV? The Ultimate Guide to Wheel Safety Standards

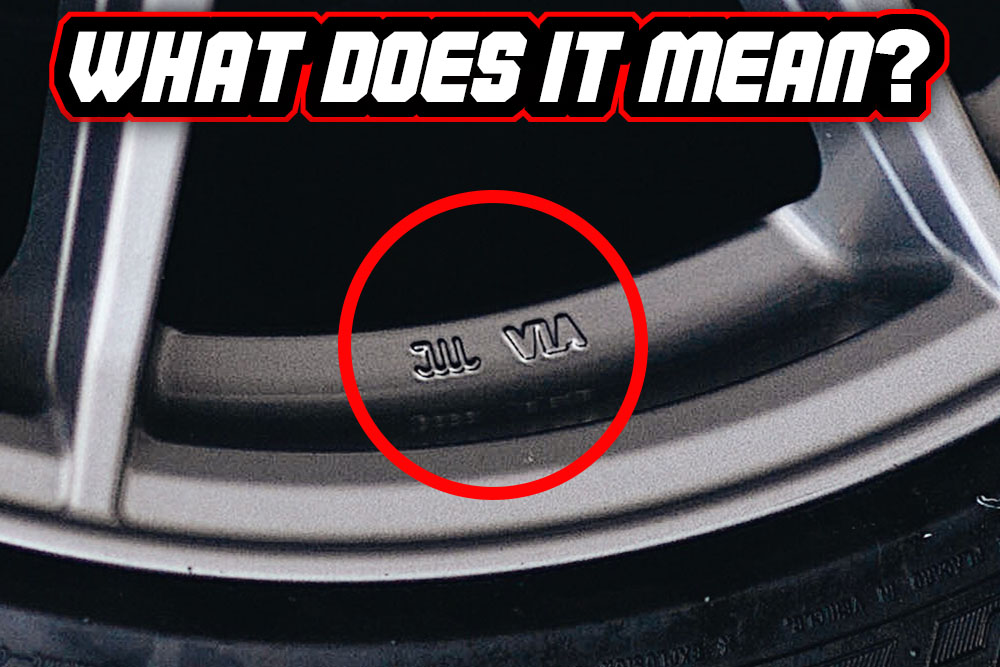

You have no doubt noticed strange markings on your wheels with random letters like JWL or VIA, or even shiny stickers with JAWA or similar.

What do these mysterious letters actually mean?

In this post, I’m going to explain exactly what they mean and why they are important.

What These Markings Are

Markings like JWL, VIA, TUV or JAWA are actually indicators that are meant to show that the wheel you are looking at has been tested and passed that particular safety standard.

Now, there are many markings on most wheels, and some of those markings have nothing to do with safety standards.

But if you see any of the letters above, that’s what they mean.

Now, why are these letters important?

Wheels are actually an important structural component of a car, and if they are weak and prone to failure it could have serious consequences.

Most people prefer to buy wheels that are not going to randomly break and fall off their car, and these markings are supposed to give you peace of mind that you have just bought a quality wheel and the chances of that happening are slim to none.

However, it’s not as simple as that.

Let’s take a look into what each of these markings actually mean, and then I will explain what the problems are.

JWL

This is probably the most common stamping you are going to see and it has many people wondering what that actually is (including my younger self).

JWL is the “Japan Light Allow Wheel Standard” and is one of the first standards introduced by the Ministry of Land Transportation in Japan back in the 1970s.

It is a series of safety tests designed to ensure that wheels meet a certain strength standard and must be met for wheels to be made or sold in Japan, even if they are not made by a Japanese company.

The JWL certification has 3 main tests:

- Impact test (13 degree) – Designed to test the wheel’s resistance to cracking if it hits a pot hole or other object. The wheel with a tire mounted is bolted down at a 13 degree angle, and a weight (determined by the spec of the wheel) is dropped onto the wheel, simulating an impact. If the wheel cracks, deforms or there is an air leak, the wheel cannot pass JWL.

- Radial fatigue test – This tests the strength of the mounting area with the PCD holes, which is crucial for load rating, making sure the wheel’s rim will not separate from the hub under force or impact. The rear of the wheel is clamped down while forces are applied to the mounting face to simulate the forces that a wheel would experience on the road. In order to pass JWL, the wheel must go through 100,000 test cycles without cracking, deforming or loosening of lug nuts.

- Cornering fatigue test – This tests the strength and integrity of the wheel during driving. With a tire mounted to the wheel, it is spun against a high pressure roller, designed to simulate the forces of cornering and the load of a car. The wheel must withstand 500,000 cycles without any deformation, cracking, loosening of lug nuts or air leaks in order to pass JWL.

The JWL standard must be met for every size, offset and PCD combination of the wheel, not just one general design.

These days, almost all wheels meet the JWL standard, including many rep wheel brands. Very few companies out there today don’t have at least the JWL certification.

However, JWL is self-certified, meaning the factory signs the wheels off themselves, indicating they have passed the test. Unfortunately, that makes it possible for manufacturers to claim their wheel is up to JWL standard when it is not, and this has been done.

This is why VIA exists.

JWL-T

JWL-T is a similar test but for truck and bus wheels. Due to the heavier and larger size of trucks and buses, the wheels designed for these vehicles must pass a higher level of test.

VIA

VIA is run by the Vehicle Inspection Association of Japan, and unlike JWL, it is a government agency that ensures that the wheel does in fact meet the standard.

The tests run by VIA are the same as JWL tests, but they are done by the outside organization rather than the manufacturer.

VIA certification is voluntary and costs money, so you will find that some manufacturers choose not to do it. When wheels have a JWL symbol but not VIA, that’s usually what that means.

Once a wheel has been VIA certified, the manufacturer gets a bound and stamped report that contains the results of the tests as well as registration numbers which can be found in the VIA database.

This is a searchable database that has all of the wheels certified by VIA, so it is possible to look up whether a set of wheels truly are VIA certified. Unfortunately, the VIA database is not public, only members have access to it.

However, every manufacturer that has done VIA testing will be able to provide the registration number. If they can’t, odds are they have not passed the test.

Wheels that are VIA certified are eligible to be certified by JAWA.

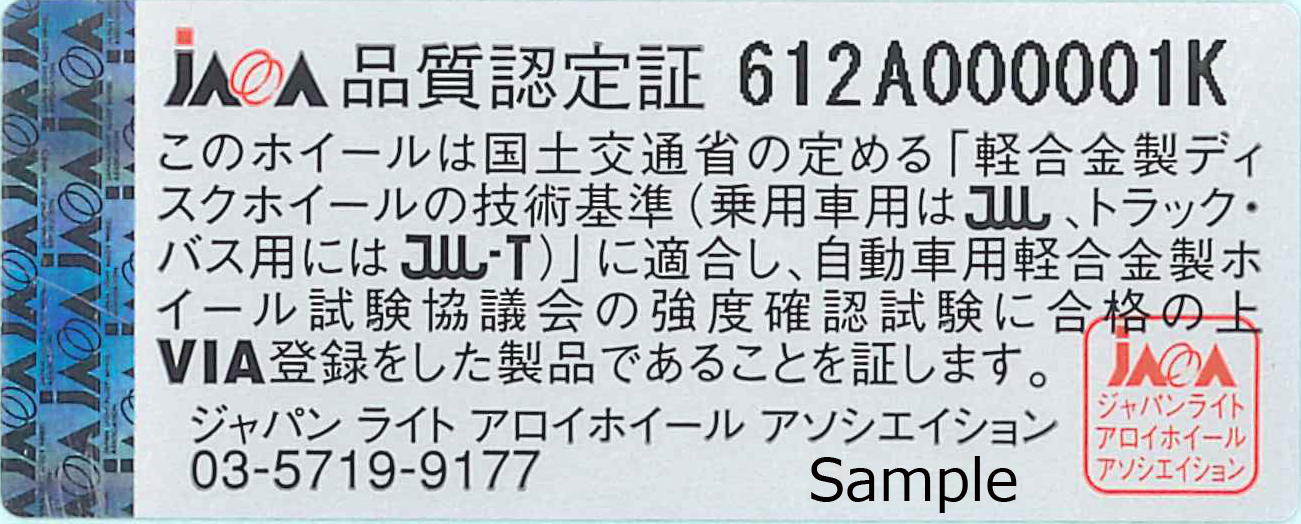

JAWA

JAWA is the Japanese “Japan Light Alloy Wheel Association”, and are essentially an auditor that provides another level of assurance that the wheels do meet the safety standard.

JAWA’s job is to maintain wheel safety and reliability, and they also have three kinds of strength tests to ensure that the wheels have passed VIA tests.

Wheels that pass the test earn the JAWA Quality Cert seal. On wheels that have passed, they will have a sticker applied to the barrel of the wheel which has a holographic image to prevent forgery and a certification number.

JAWA also has a “design deposition system” which is designed to prevent copying wheel designs.

They are essentially another layer or confirmation that a wheel truly has passed both VIA and JWL. If a wheel has all 3 certifications, you can be sure it has met the standards. However, not many wheels have the JAWA certification.

TUV

TUV is the European certification and covers many things from toys to car parts. They have a specific TUV standard when it comes to wheels, which applied in Germany, Switzerland and Austria.

The TUV standard is one of if not the toughest one out there, as is required for wheels sold and used in the countries mentioned above.

To get a TUV certification, the manufacturer must first pass ISO9001/2000 which are standards for the quality of materials they are using, and must be TUV certified as a manufacturer.

That means if you are selling wheels that someone else makes for you, you can’t get TUV certified, they have to get certified.

This process involves passing an audit every 3 years by TUV authorities from Europe. This audit is similar to the ISO 9001 audit and is designed to ensure consistent quality of manufacture.

Once the manufacturer gets the certification, they can then send wheels to Europe to get individually tested and certified.

In order for wheels to get TUV certified, every wheel size, offset and PCD must be tested and approved for every particular car it is designed for.

This is obviously a very time consuming and costly process, which is why many wheel companies don’t do it, especially since it is not required outside of Europe.

TUV wheel checks include:

- Durability tests for custom wheels

- Bending fatigue tests

- Rim-rolling tests

- Impact tests

- Corrosion tests

You can check if a manufacturer is TUV approved by looking up their TUV ID on the TUV website: https://www.tuv.at

Why Are These Standards Necessary?

When the aftermarket wheel industry began taking off in the 70s and 80s there was no standard for wheel manufacturing, and many wheel manufacturers were just pumping out an enormous amount of low quality wheels which was flooding the marketing and making it hard to differential between these wheels and good quality wheels like Volk, BBS and SSR.

Factories were popping up all over the place that would make any wheels for a cheap down payment for the mold design, and wheel companies would sell these wheels for as low as $400 a set – you can probably imagine what the quality of those wheels was like.

Due to this, standards starting coming out from the various countries producing wheels including Japan, Germany and even Mexico for a period.

Nowadays, wheel manufacturing standards have significantly improved, but you still get many poor quality wheels that are miles off from the quality of a good wheel.

Without some kind of standard to keep things in check, it would be very difficult to tell which wheels were good and which weren’t.

Here is a good video from Weds showing the difference between one of their wheels and a fake wheel that does not meet JWL standards:

The Problem With the Symbols

One major issue when it comes to the markings is that it is not very well enforced.

Some wheels that don’t have the stamps CAN be certified, and others that DO have the stamp may NOT be certified.

The JWL, VIA and JAWA markings are only enforceable in Japan, so a company outside of Japan who does not plan to sell wheels in Japan can in fact make wheels with these markings and no one could do much about it.

While technically it is a breach of trademark law, it’s not really enforced.

This is a genuine problem and you have many cheap and replica wheels that have the JWL and even VIA symbol yet they were never put through the test, let alone passed.

Unfortunately, because the Japanese government doesn’t release the database publicly, there is no real way for the average person to check if a wheel has truly got the certifications.

The other problem you have is with JWL being self-regulated, some wheel companies choose to stamp the symbol even though technically their wheel doesn’t actually meet the standard.

So just because a wheel has the markings, doesn’t actually mean that it meets the standards.

How Important Are These Standards Really?

Back when most of these standards were introduced there really was a need to differentiate between the countless rubbish wheels that were on the market and the good quality wheels made by reputable companies, especially since most of them were new at the time.

Personally, I think it’s still good to have some sort of reference point you can check against. While I’m all for allowing people to buy and sell whatever they want, and think that the TUV regulation is way overboard, I do think some kind of standard is necessary for the people who want to make quality wheels, and the ones who want to buy them.

So while I wouldn’t base my wheel purchasing decision solely off whether a wheel has JWL or VIA, they just add another level of assurance that the wheel is made to some kind of standard (assuming they did actually pass).

America Does Not Have a Wheel Safety Standard Requirement

One thing to be aware of is that America doesn’t have any safety standard requirements when it comes to wheels.

This is why you see many American wheel companies that have no mention of any wheel certifications, including the better ones like Rotiform.

This doesn’t mean that their wheels are low quality, it just means that it can be harder to tell which brands actually make good wheels and which don’t, because wheels don’t have to pass any test in order to be sold.

In cases like these, you are left to judge based on the information the company gives you, their manufacturing processes and other people’s experiences.

How Can You Be Sure You Are Getting Safe Wheels?

Despite all these standards, the only real way to be sure you are buying good quality wheels that won’t suddenly fall off is by buying from the known manufacturers such as Enkei, Volk, BBS, Work, SSR and so on.

The best wheel brands have proven themselves over the years, especially the ones involved in motorsport, so you are able to see which ones produce wheels that last and which just have good marketing but can’t show any proof.

When it comes to new wheel brands, it can be harder to tell how good they are, so it’s in their favour if they choose to get certified, particularly if they choose to pass the harder certifications such as VIA and TUV.

Keeping a lookout for these certifications can add an extra layer of assurance that these companies are doing their best to produce quality wheels, as long as they are genuinely certified.

If they are claiming to have the certifications but they actually do not, you should be asking yourself where else they are willing taking shortcuts.

- BC Racing BR Series VS Tein Flex Z Coilovers - April 15, 2024

- The Pros and Cons of Shock Body Vs Spring Perch Coilover Height Adjustment - April 13, 2024

- Monotube Vs Twin Tube Shocks: The Ultimate Guide - April 11, 2024